The new Lp Gas regulations South Africa - SANS-10087-1-2024-(Edition 7) Please note, we are still in the process of updating this page.

The new Lp Gas installation regulations 2024

30 Aug 2024— The new standard has now been released after years of hard work from multiple members associated in the gas industry. You may find yourself confused to what standard applies to your existing or new installation.

According to the gas regulations SANS-10087-1-2024, All fixed gas installations must have a Certificate of Conformity ( CoC )/ Gas compliance certificate.

* Existing gas installations that require an updated CoC for insurance purposes or for whatever reason where the property does not change names will still follow the old SANS 10087-1:2013. If any major amendments are needed, The installation will need to be upgraded to the new standard (SANS 10087-1:2024 Ed7).

* New gas installations will need to be installed according to the new SANS-10087-1-2024 ed7 standard.

Do you have a gas line installation? And are you concerned about the legality of the installation?

We have provided some information below from SANS for you to compare it with your current installation or to get an idea for a future installation.

This will help to confirm that your installation or future installation meets the necessary standards and regulations .

Digital Gas Certificate Of Conformity

Gas Certificate Of Conformity

- Please be aware that The Gas Association has phased out paper Certificates of Compliance (CoC's) in favor of a digital format CoC.

- Installations should be inspected at regular intervals not exceeding 5 years. An updated CoC shall be required in order to comply.

- Insurance companies will have inhouse rules where an inspection may be required annually.

- An updated CoC will be required for the sale of a property . This is to ensure the purchaser is protected with a compliant installation and perishable parts have been replaced.

- Upon a gas installation completion, the installation shall be inspected, tested and approved by the registered installer. The user shall be issued with a SAQCC digital certificate of compliance that indicates that the installation has been tested and that it complies with SANS-10087-1-2024-(Edition 7).

🔥 Click here to get compliant today! 🖱️

Internal Cylinder Placement

NOTE 1 -

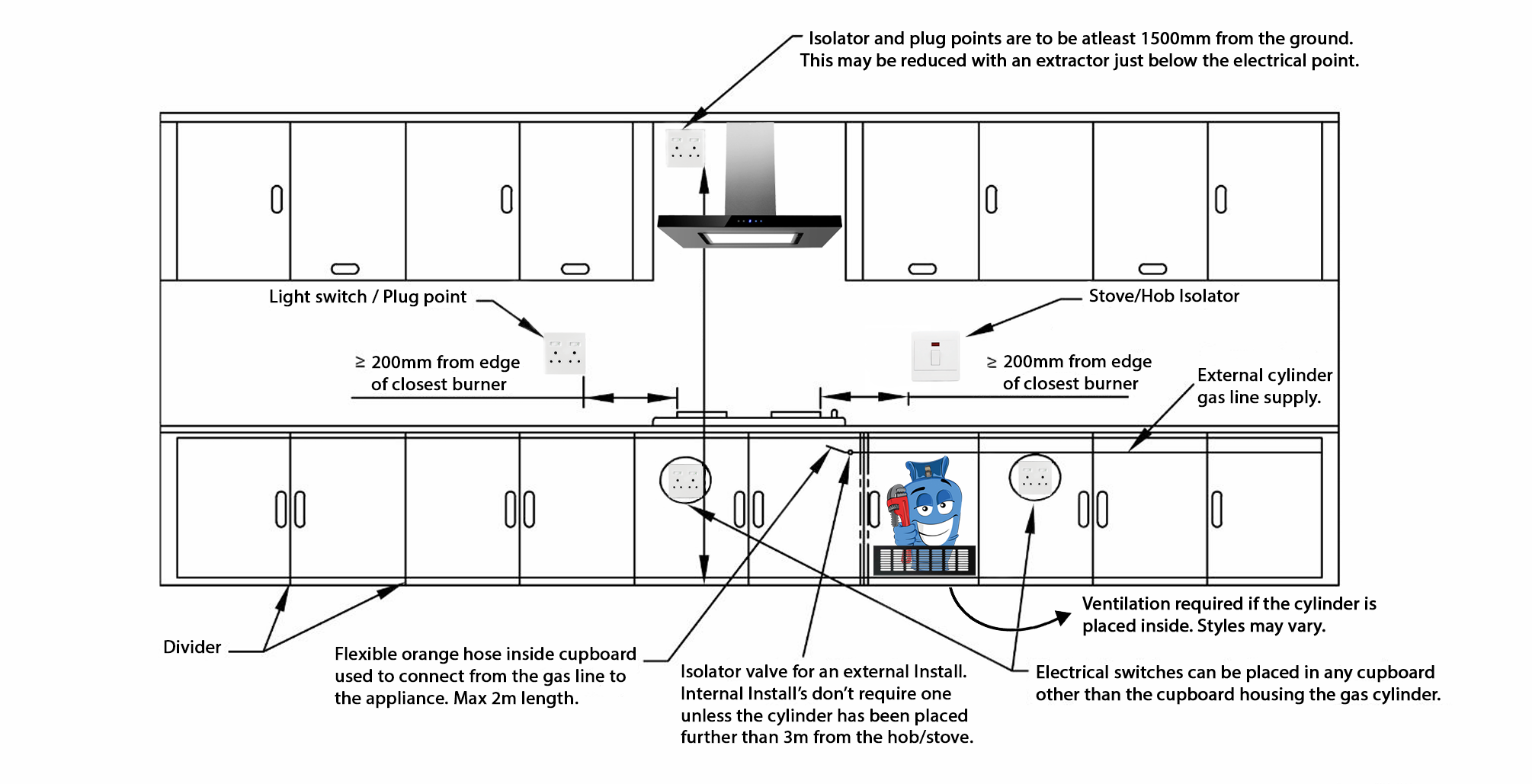

- Orange hose is for indoor use only. It may not pass through any solid partitions. Only to be used to connect to appliances/Bullnose.

- Where a gas container needs to be placed inside a cupboard, the cupboard shall have permanent ventilation.

- Where a single appliance and container are located within the same room not exceeding 3 m apart, the

container valve may be considered as the emergency shut-off valve. - No electrical connections or plug points shall be allowed in the same partition as the gas container.

- It is now allowable to place an electrical switch Below or Directly behind a gas hob or stove.

- Any electrical switch above the stove or hob needs to be 1500mm from the ground or this may be reduced if an extractor fan is installed below the switch.

- All other electrical switches ( Isolator Switch ) between the burner and extractor must be at least 200mm to the left or right of the appliance.

Continue Reading +

- Internal Installations for houses (including cluster housing and group housing (not exceeding two storeys), a total maximum of 19 kg is allowed to be installed inside.

- e)Flats are allowed a maximum of 9 kg per flat.

- f)No fixed installation shall be installed inside a garage.

External Cylinder Placement

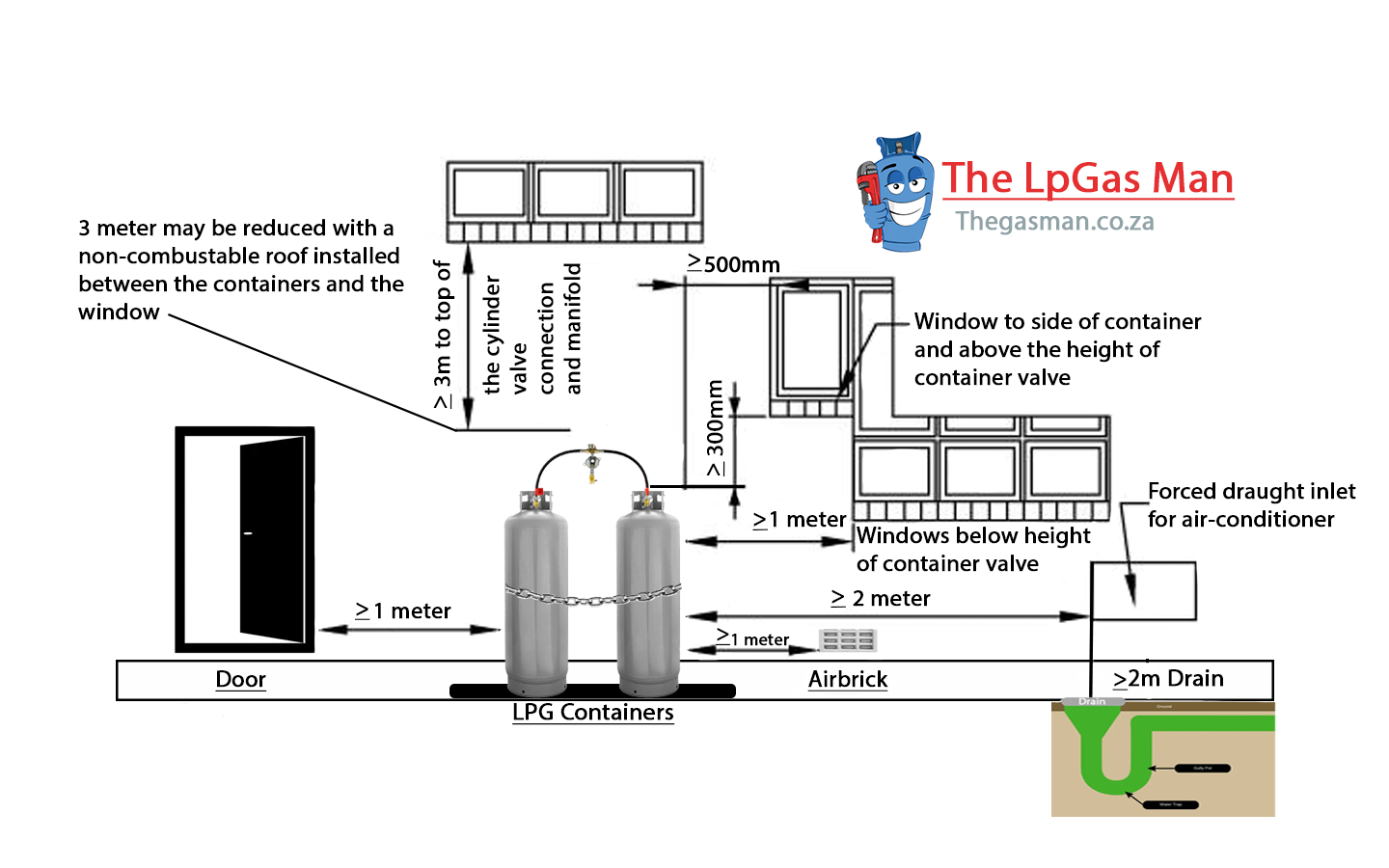

Cylinder placements and distances.

Containers shall be at least

- a) 1 m away from any opening (into a building) that is below the level of the container valve, i.e.

doors, windows and airbricks. - b) 2 m away from any drain, pit or manhole and forced draught inlet's.

- Distances may be reduced from windows dependent on height and weather a non combustible roof has been installed. Eg: Cage

Continue Reading +

- h) Cylinder/s are to be placed into a cage if your property has public access not restricting them from entering.

- i) A total of 100kg's is allowed outside per a ERF number. If a property requires more than the allowed 100kg's, The property will require fire department approval with drawings showing the propossed location and setup. In some cases, Your local bylaws may differ to the allowed maximum allowance.

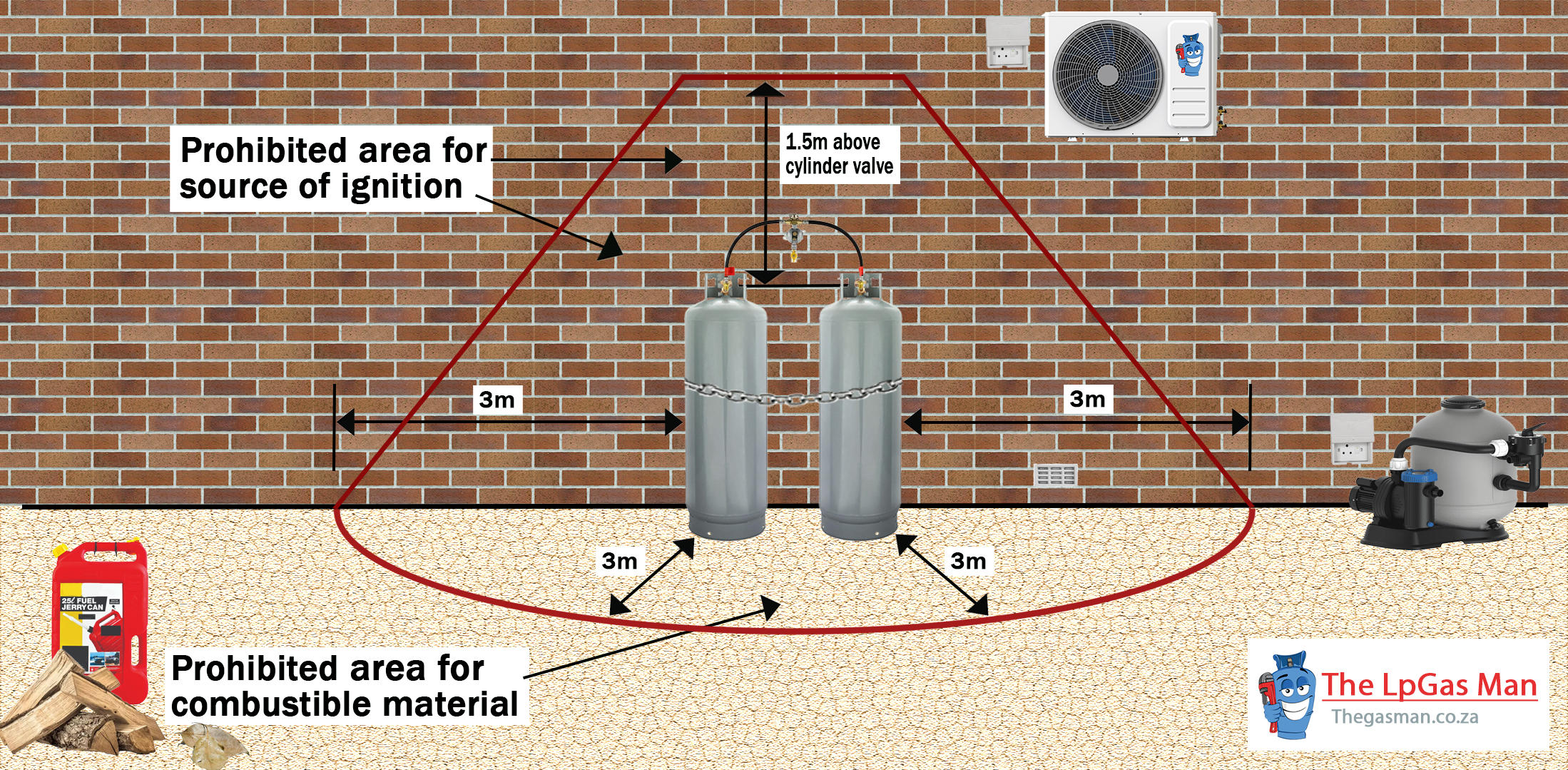

Minimum distance from Source Of Ignition

The new and reduced minimum distances.

- If below the gas valve, A minimum of 3m is required from the cylinder to a electrical source of ignition such as outside plug points, distribution boards, motors, pool pumps, generators etc. This may be reduced to 1.5m if placed above the cylinder from valve to the source of ignition.

- A distance of 3m from combustible materials. Containers shall be located on a firm, clean, well-drained and level base. The area surrounding a container shall be kept clear of combustible materials, for example, weeds, dry grass, paper, waste and other flammable materials or chemicals.

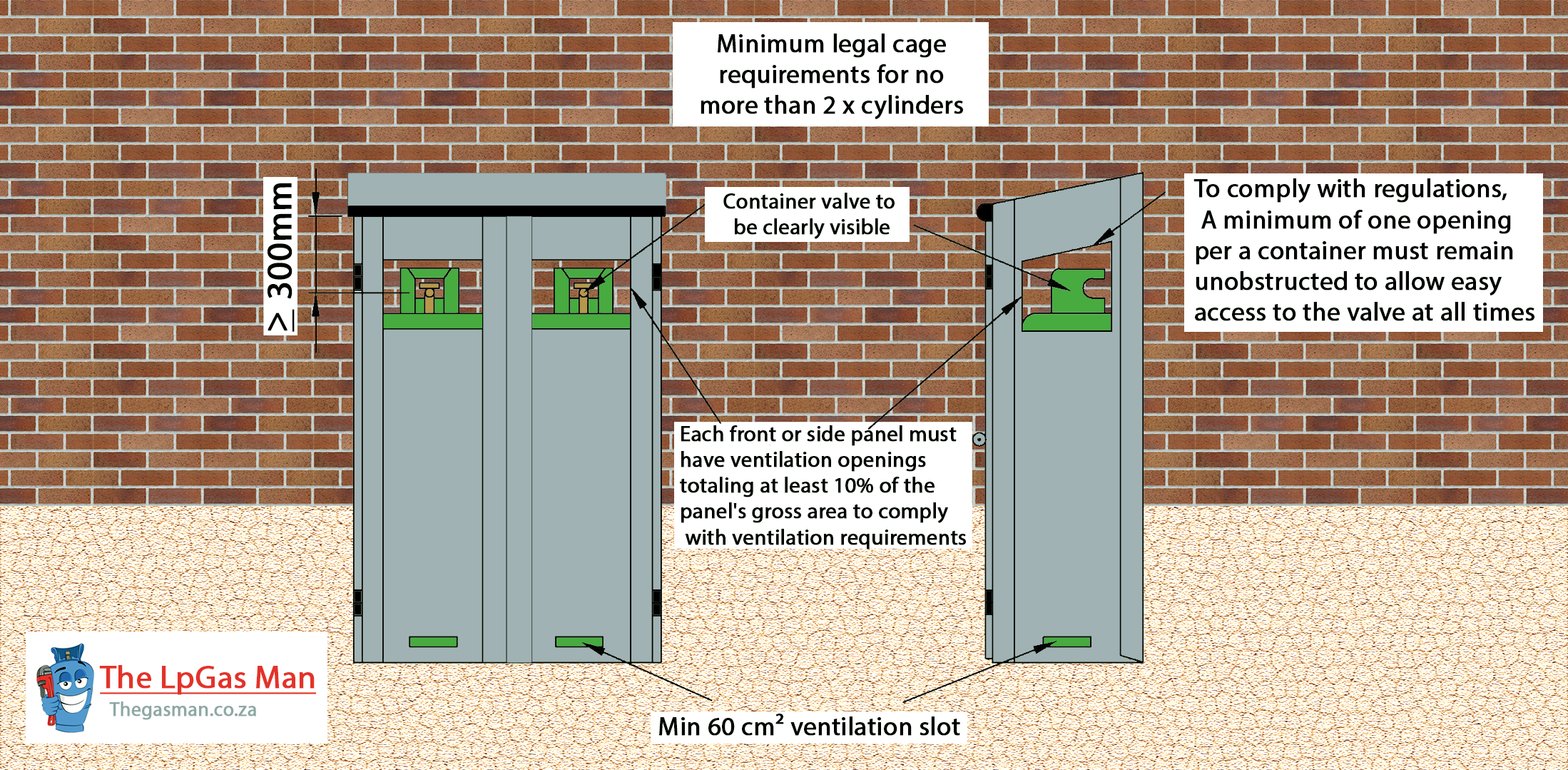

Cage requirements not exceeding 100kg's or 2 containers

The new gas cage requirements.

- Enclosure requirements for installations consisting of individual containers not exceeding 50 kg and the total capacity not exceeding 100 kg or 2 containers.

- Container valve to be clearly visible.

- Min 60 cm² ventilation slot at the bottom of enclosed cage.

- At least one opening to be left open per container, Such that the container valve can be easily closed by hand.

- Cage to be securely mounted in 4 corners.

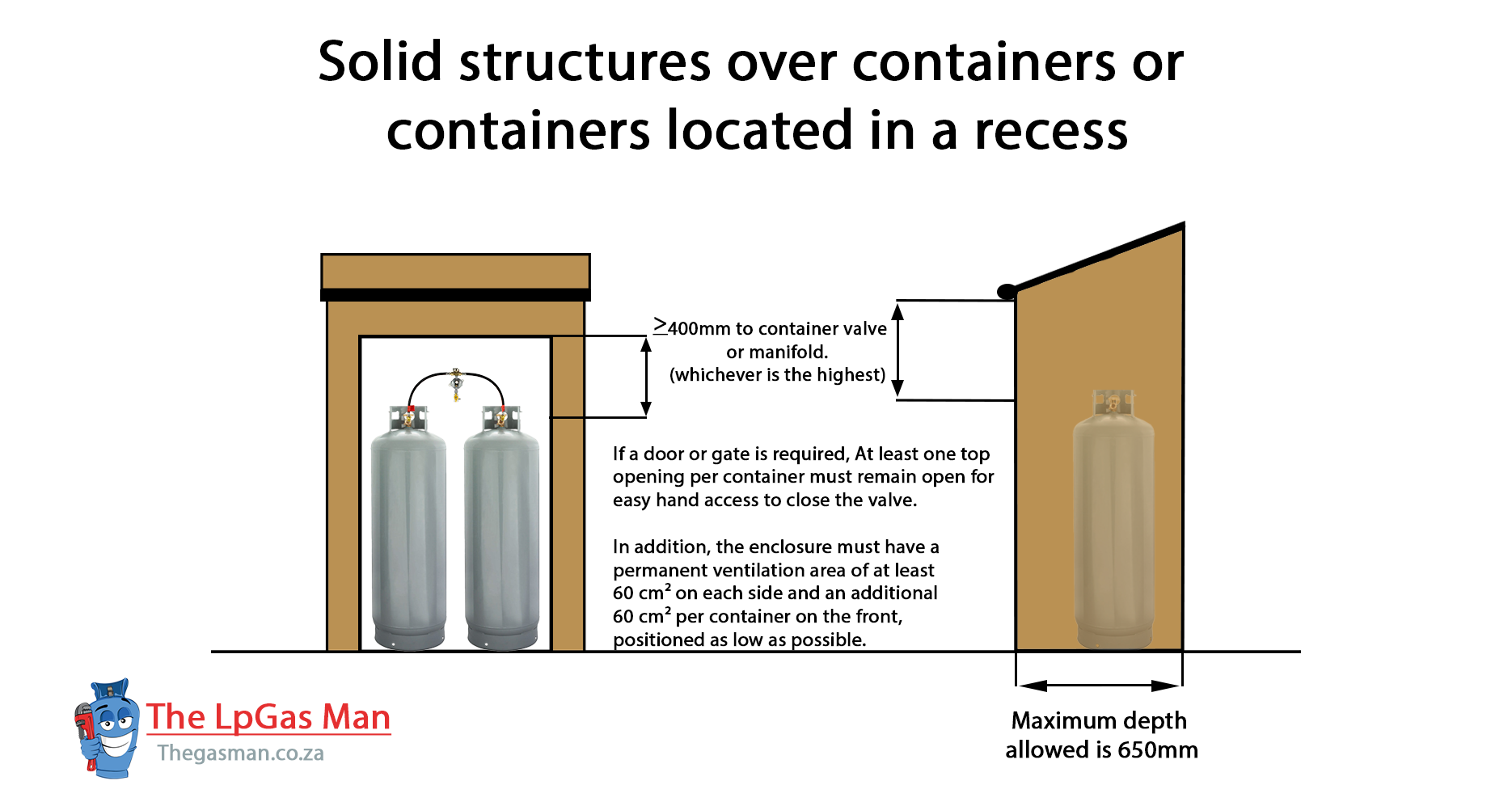

Solid structures over containers or containers located in a recess

Any enclosure, whether required by the standard or elected to be used shall meet the requirements

Structures such as firewalls, concrete barriers, and other similar structures shall be avoided around

or over installed containers.

The following are exceptions to these requirements:

- Where concrete barriers, and other similar structures are unavoidable above the installed containers, the

distance between container valves, manifold or regulator (whichever is the highest) and such structure,

shall not be less than 400 mm. - The space created by the structure shall not be deeper than 650 mm

- If a door or gate is required for the enclosure, the ventilation requirements shall be met.

🧯Fire Department Approval Needed For Over 100Kg's Of Gas

We provide a comprehensive fire department approval service for both residential and commercial properties that have, or require, more than 100 kg of gas connected to a fixed gas installation or multiple installations on the same ERF or stand number. Our service includes detailed gas layout drawings and all necessary documentation for a smooth and successful submission process.

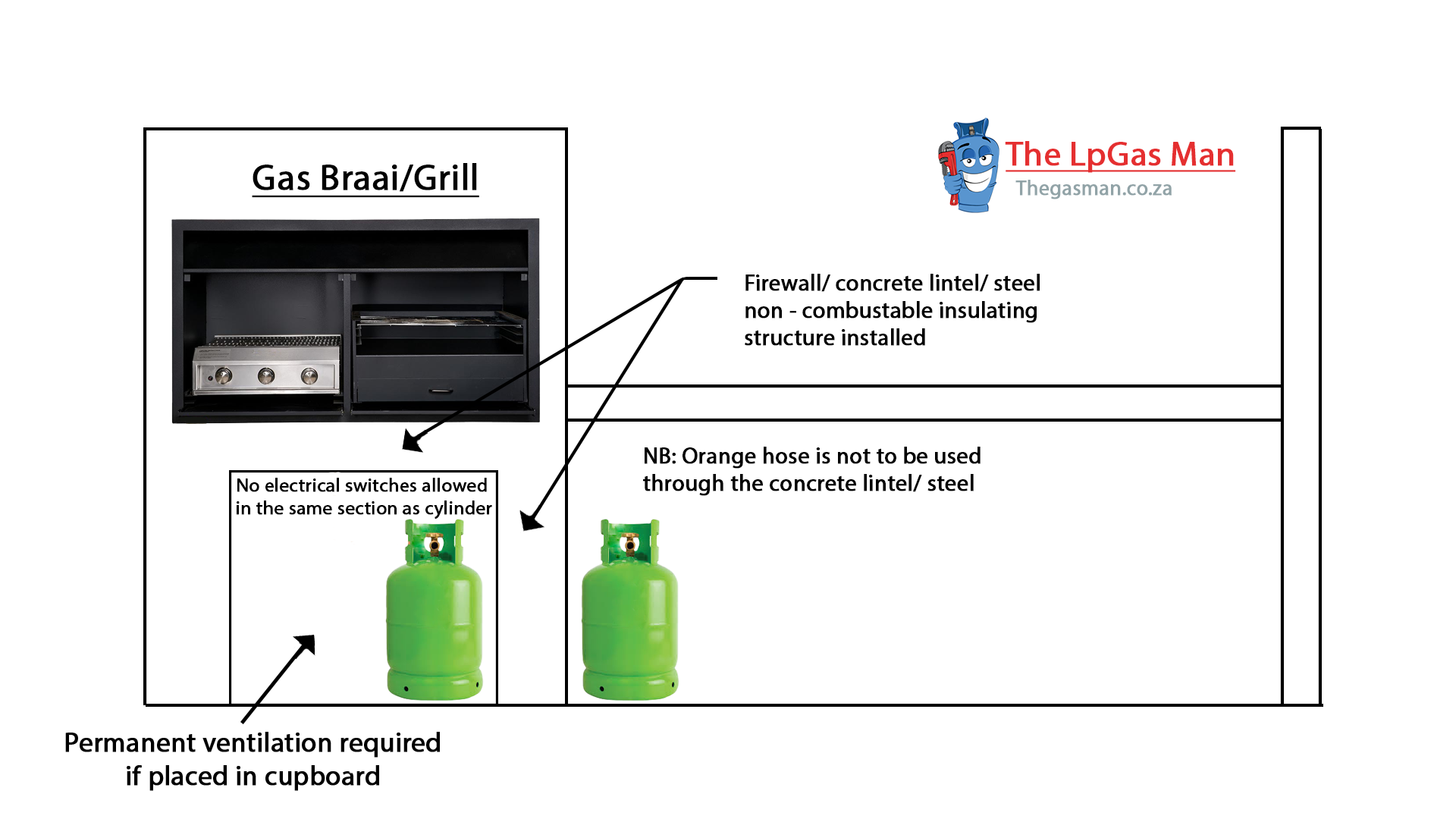

Patio Gas Braai/Grill Placement

Collapsible row

- Where a gas container needs to be placed inside a cupboard, the cupboard shall have permanent

ventilation available, for example airbricks, lattice door(s), or ventilation slots. - No electrical connections or plug points shall be allowed in the same section as the gas container.

- Only one container with a maximum capacity of 9 kg may be installed per cupboard, and no other items shall be

stored in the section of the cupboard containing the gas container.

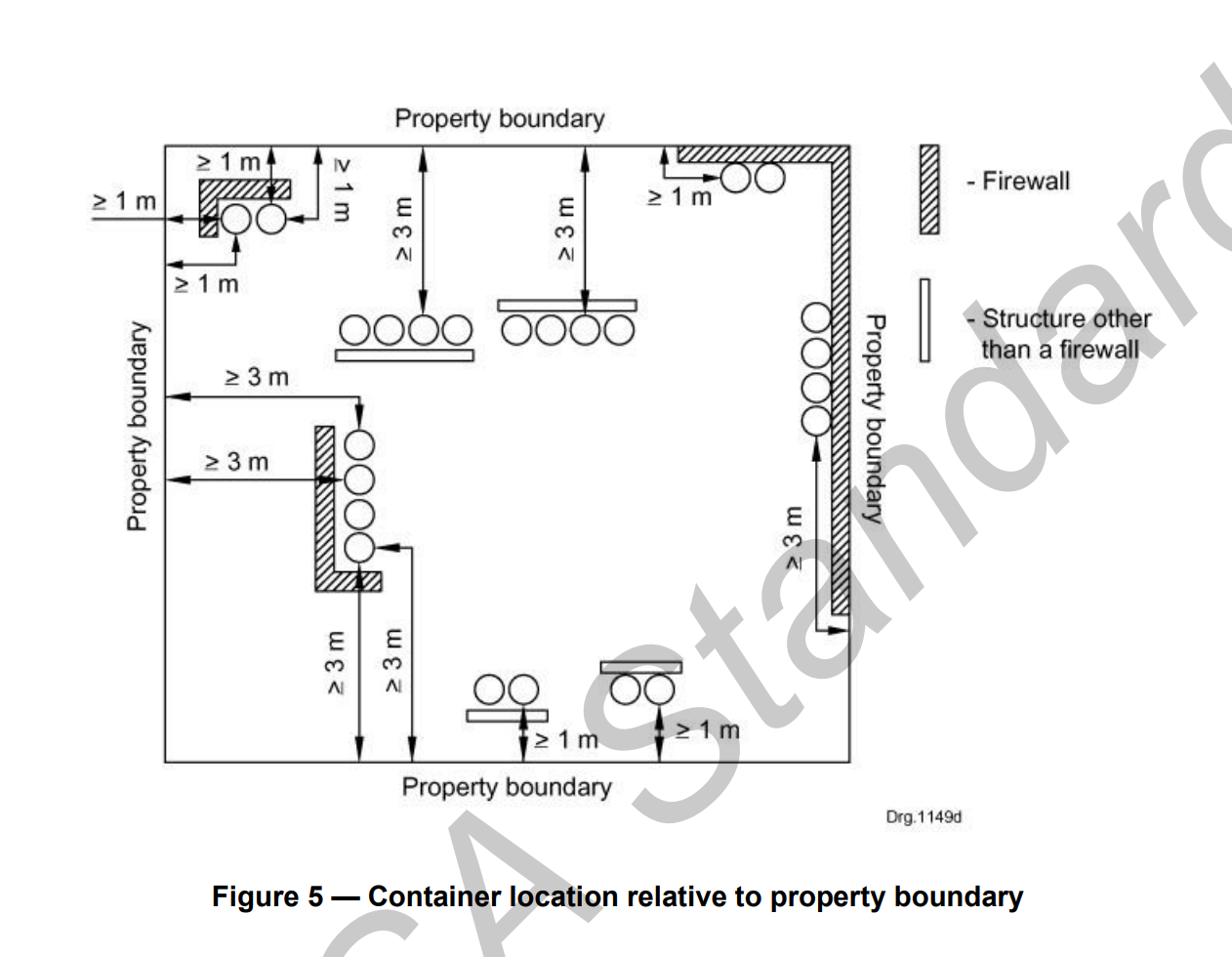

Boundary Wall Requirements

Boundary wall and drain Distances

NOTE 1- The minimum required distance from a boundary wall other than a firewall is 1m. Over 100kg's will be 3m.

NOTE 2- This may be reduced or placed directly against the boundary if a firewall that meets requirements has been used.

Inspection and maintenance (Manifolds and pigtails)

The manifold system should be maintained on a planned inspection basis at intervals not exceeding five years. NOTE, If pigtail/s are exposed to high UV conditions, this period should be reduced.

Continue Reading +

1- A check shall be made to ensure that all safety distances are maintained.

2- Where applicable the enclosure shall be inspected for the condition of any fencing or walling, including the gate. The prescribed signage shall still be in place and legible. ( Commercial or over 100Kg's of gas on a property.

3- The enclosure and immediate surroundings shall be cleared of any uncontrolled weed growth and accumulation of waste products.

4- Repair and maintenance shall only be carried out by a registered installer and the faults in the installation shall be rectified in accordance with the requirements of this part of SANS 10087.

5- Flexible pigtails shall be inspected for signs of rupture, cracking, chafing and perishing and shall be replaced if necessary. If flexible pigtails are over five years old they shall be replaced automatically.

6- The brackets that secure the manifold shall be checked for soundness.

7- The pipework shall be checked for corrosion.

8- All valves shall be checked for free and full range of movement, leakage, positive shut off,

corrosion and mechanical damage.

9- The hydrostatic relief valve on liquid manifolds shall be inspected for corrosion and for any ingress of foreign bodies into the operating mechanism. The relief valve shall be replaced if it is more than five years old.

10- The regulator shall be checked for corrosion and mechanical damage. Where corrosion or

mechanical damage is found the regulator shall be replaced or refurbished.

11- If fitted, gauges shall be checked for correct operation, and gauge faces shall be cleaned.

12- The system shall be leak-tested at all joints using a leak detection solution or system. All

joints where leaks become evident, shall be tightened or remade after the system has been

depressurized.

Contact us on +27 79-586-9947 or fill in the below and we will get back to you.

Why choose us?

As a renowned provider of gas installations, our team with years of experiance are highly skilled and fully registered technicians are dedicated to following all applicable regulations and best practices to guarantee the excellence and safety of our services and our clients. We offer personalized consultations to assist you in determining the most suitable gas line layout and cylinder placement for your specific needs and requirements. With a deep understanding that each customer has distinctive needs, we adopt a customized approach to every project By closely collaborating with you to comprehend your unique requirements. We can deliver tailored solutions that fulfill your needs and surpass your expectations.

Call – 079-586-9947

- Gas Installations Fourways

- Gas Installations Broadacres

- Gas Installations Bryanston

- Gas Installations Dainfern

- Gas Installations Dainfern Ridge

- Gas Installations Douglasdale

- Gas Installations Duxberry

- Gas Installations Edenburg

- Gas Installations Jukskei Park

- Gas Installations Kyalami