THE NEW SANS-10087-1-2024-(Edition 7) Has been released on the 30th of August 2024. The below code SANS 10087-1-2013 will only apply to existing installations that can produce a CoC. CLICK HERE FOR THE NEW SANS 10087-1-2024 GAS REGULATIONS

The LpGas Man

According to the regulations SANS 10087-1:2013, All fixed gas installations must have a Certificate of Conformity.

Do you have a gas line installation? And are you concerned about the legality of the installation?

We have provided some information below from SANS for you to compare it with your current installation or to get an idea for a future installation.

This will help to confirm that your installation or future installation meets the necessary standards and regulations .

Alternativly, contact us today for assistance in verifying its legality. This will ensure that your gas line installation or future installation is safe and compliant with the necessary standards.

Gas Certificate Of Conformity

Gas Certificate Of Conformity

- Please be aware that The Gas Association has phased out paper Certificates of Compliance (CoCs) in favor of a digital format for CoCs.

- Installations should be inspected every 5 years. An updated CoC shall be provided.

- Insurance companies will have inhouse rules where an inspection may be required annually.

- An updated CoC will be required for the sale of a property. This is to ensure the purchaser is protected with a compliant installation and perishable parts have been replaced.

- Upon a gas installation completion, the installation shall be inspected, tested and approved by the registered installer. The user shall be issued with a certificate of compliance that indicates that the installation has been tested and that it complies with this part of SANS 10087. A copy of the certificate of compliance shall be sent to a body appointed by the Chief Inspector of the Department of Labour for record purposes.

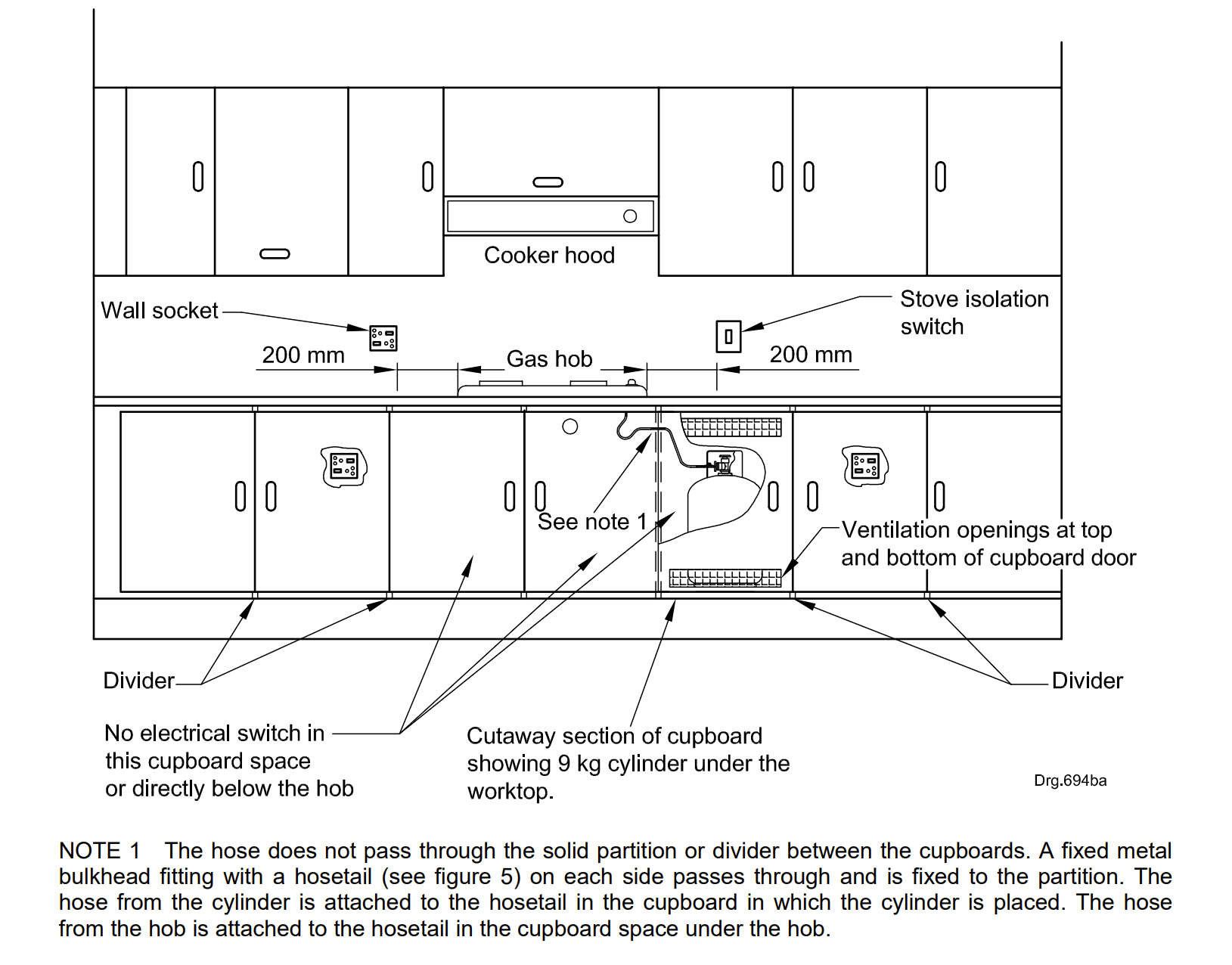

Internal Cylinder Placement

NOTE 1 -

- The Orange hose is not to exceed 2m and does not pass through any solid partitions/divider, walls, concrete etc. The hose from the hob is attached to the hosetail in the cupboard space under the hob or behind the stove and then onto either Copper class 2 or Pex. At this point we can then pass through partitions etc.

Continue Reading +

- a)Cupboard housing cylinder is to be vented

- b)Electrical Isolation switch is to be a minimum distance of 200mm either to the left or right of the appliance. It is not allowed to be below or above unsless an extractor has been put inplace.

- c)Electrical switches and plug points are not allowed below the hob or at the back of a stove.

- d)Internal Installations for houses (including cluster housing and group housing (not exceeding two storeys), a total maximum of 19 kg is allowed to be installed inside.

- e)Flats are allowed a maximum of 9 kg per flat.

- f)No fixed installation shall be installed inside a garage.

External Cylinder Placement

Cylinder placements and distances.

Containers shall be located on a firm, clean, well-drained and level base. The area surrounding a container shall be kept clear of combustible materials, for example, weeds, dry grass, paper and waste. Containers shall be located and protected against tampering by

unauthorized persons and also damage and interference by, for example, animals and vehicles.

Continue Reading +

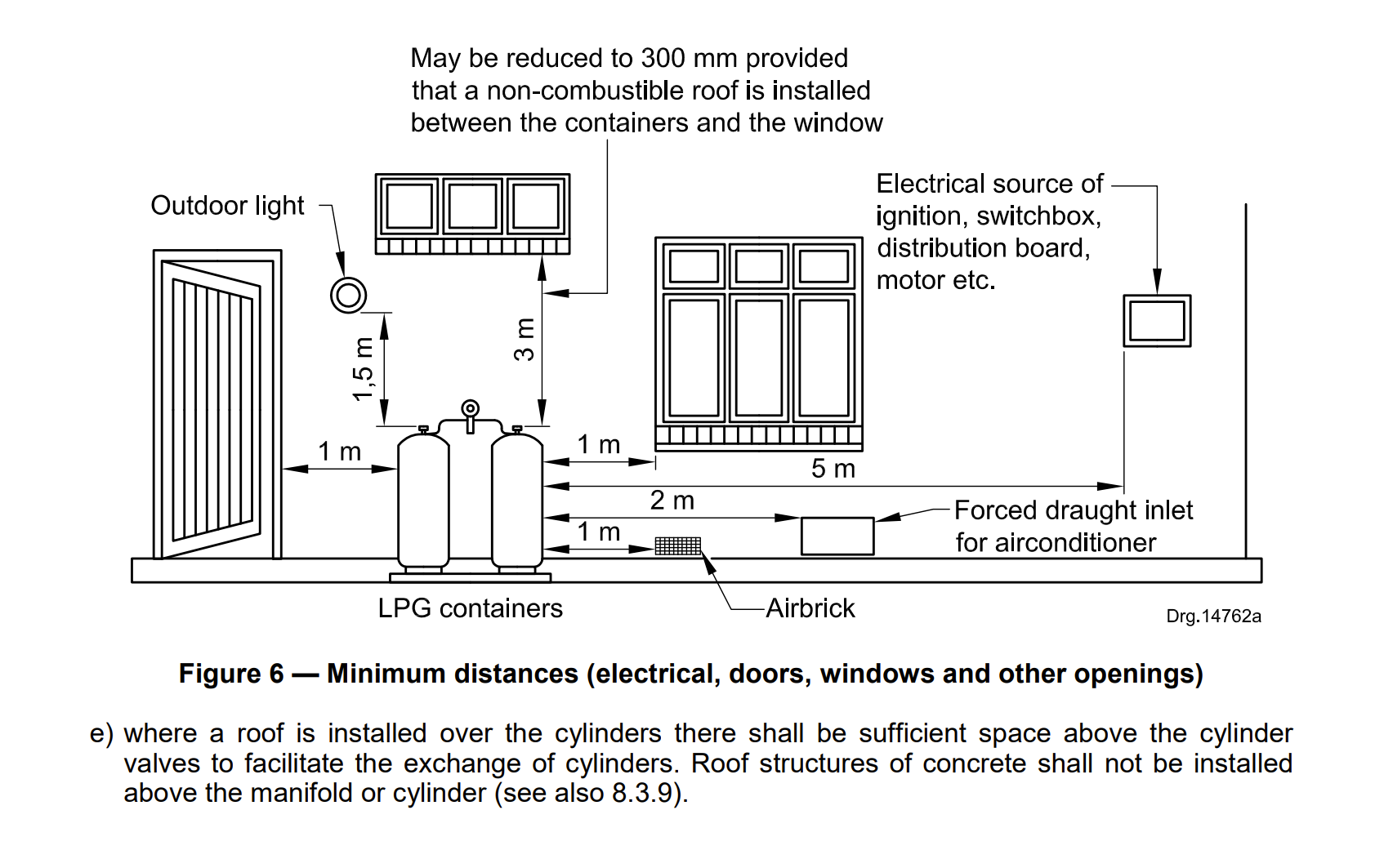

Containers shall be at least

- a) 1 m away from any opening (into a building) that is below the level of the container valve, i.e.

doors, windows and airbricks, - b) 2 m away from any drain, pit or manhole.

- c) 3 m away from the property boundary, unless the boundary has a firewall, in which case the containers could be next to the firewall (see figure 8), and where there are only two containers, the boundary distance can be reduced to 1 m.

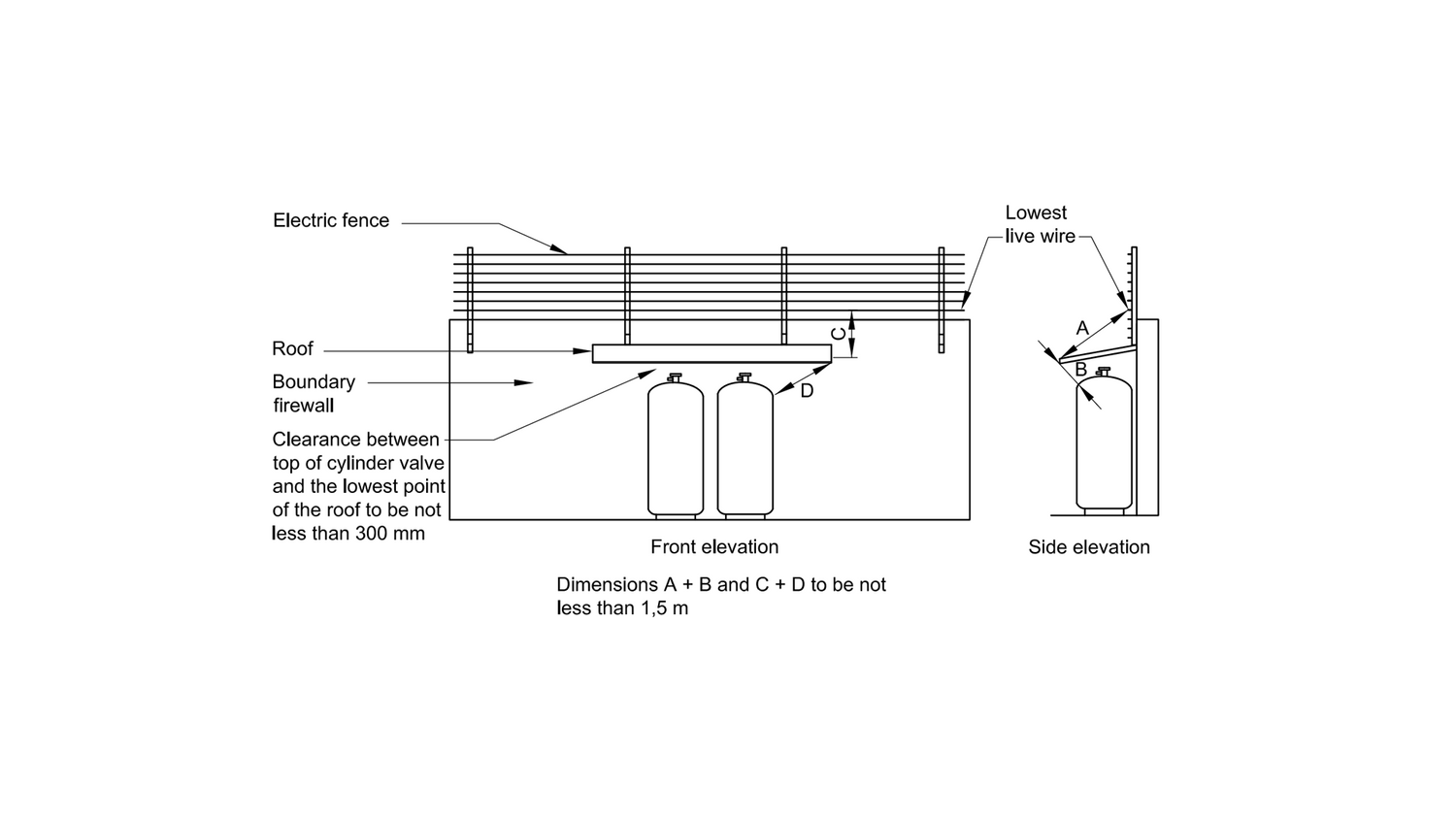

i) Cylinder/s under electric fencing is to be placed into a cage to reduce distances.

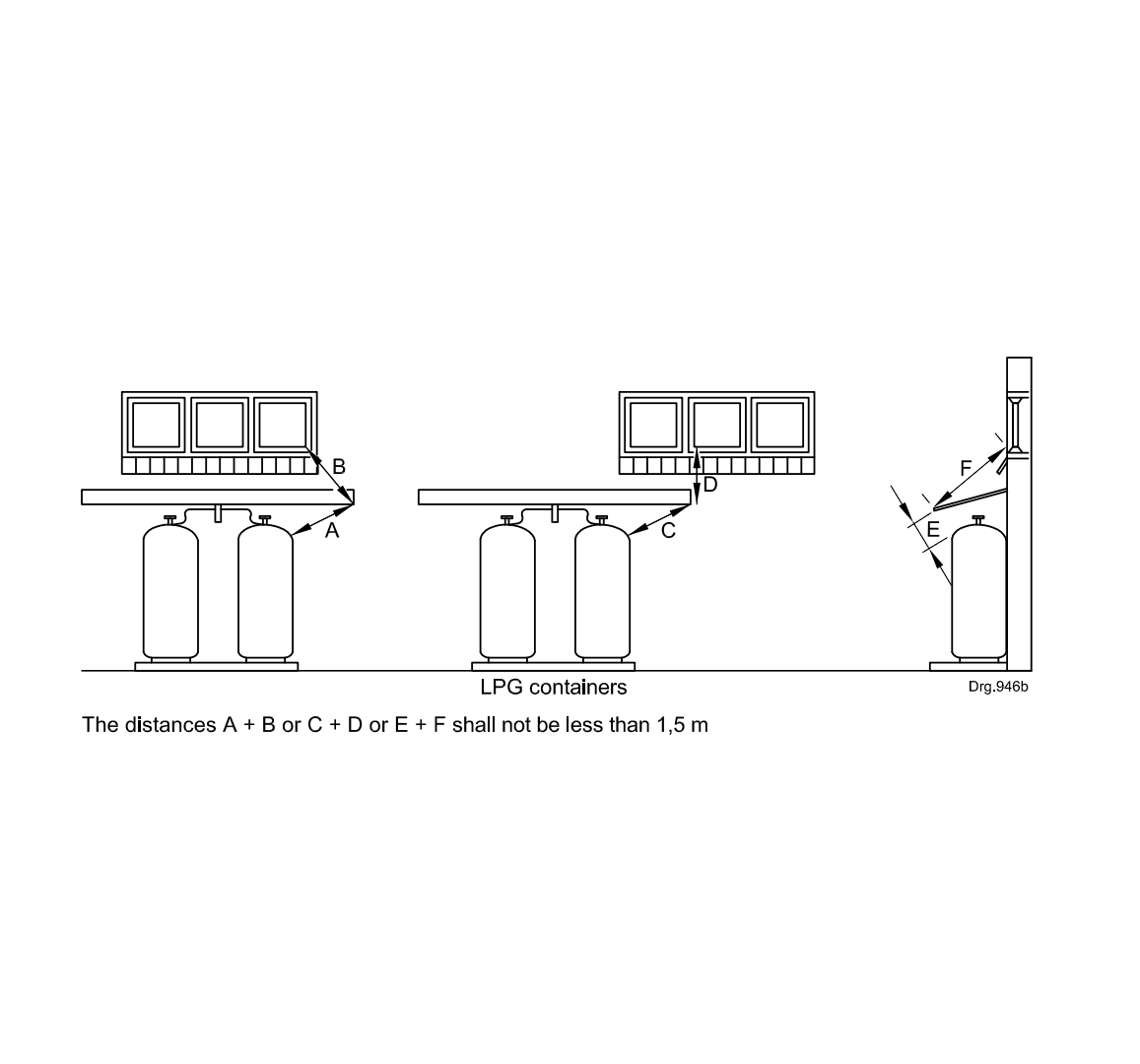

- d) 3 m away from any opening (or window) directly above the containers. The 3 m distance from the top of the cylinder, valve connection or the manifold whichever is the higher, to the bottom of the

window(s) may be reduced to a minimum of 300 mm providing that

i) a non-combustible roof (see SANS 10400) is installed between the containers and the

opening. The roof shall extend beyond the cylinder(s) such that when measured from the

valve connection and around the roof to the nearest point of the window a minimum of 1,5 m

safety distance shall be obtained, or

ii) the window frames shall be steel and the total size of the glazing does not exceed 1 m2.

* Glazing shall be of wire woven glass not larger than 450 mm × 450 mm per pane. Such

windows shall not be openable.

- e) Where a roof is installed over the cylinders there shall be sufficient space above the cylinder valves to facilitate the exchange of cylinders. Roof structures of concrete shall not be installed above the manifold or cylinder.

- f) A minimum of 5m is required from a electrical source of ignition such as outside plug points, distribution boards, motors, pool pumps, generators etc.

* If the source of ignition has been contained in an air/water tight housing, This minimum distance is not a concern but we keep a distance of atleast 1m away from the cylinder/s.

- h) Cylinder/s are to be placed into a cage if your property has public access not restricting them from entering.

- i) A total of 100kg's is allowed outside per a ERF number. If a property requires more than the allowed 100kg's, The property will require fire department approval with drawings showing the propossed location and setup. In some cases, Your local bylaws may differ to the allowed maximum allowance.

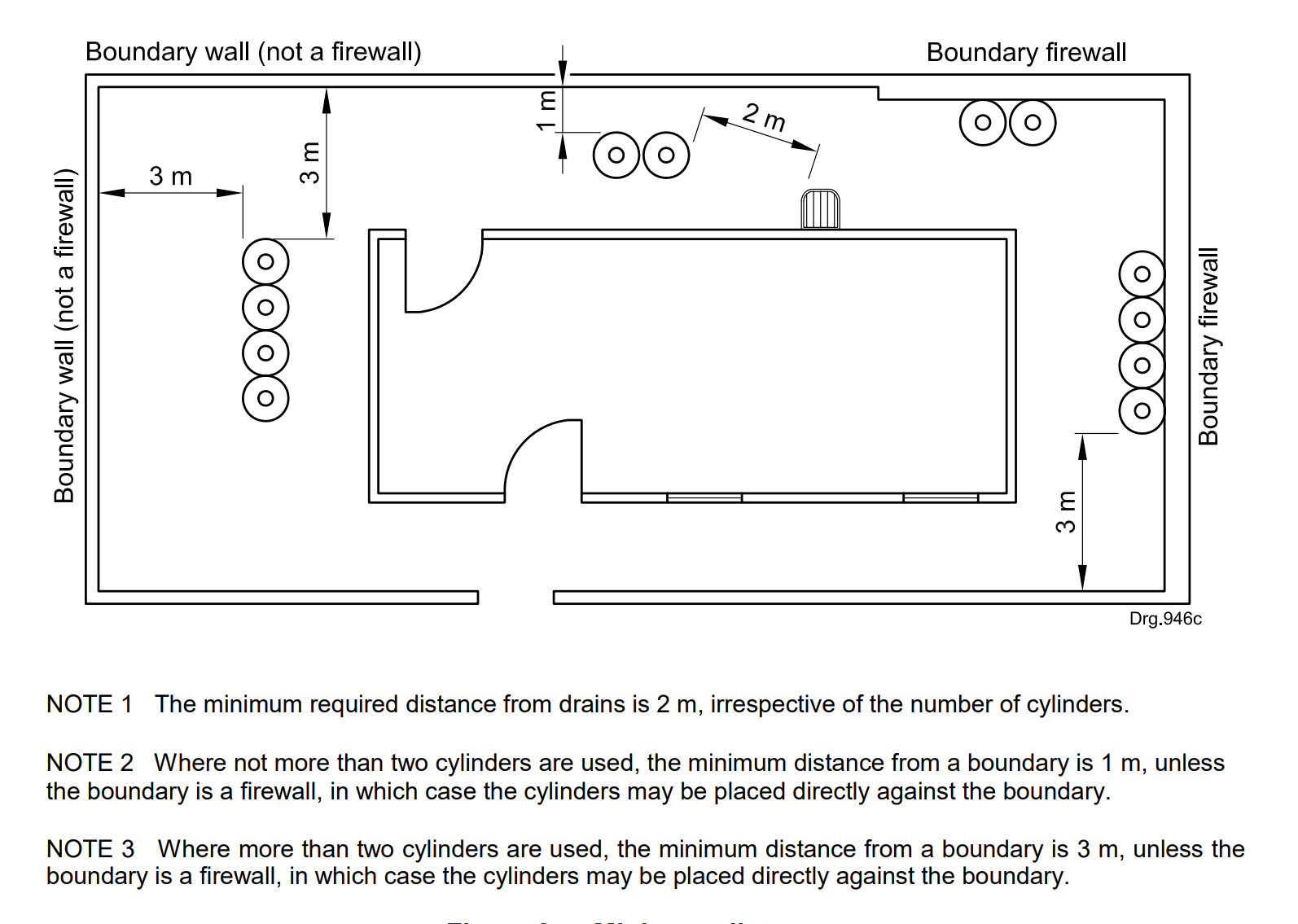

Boundary Wall Requirements

Boundary wall and drain Distances

NOTE 1- The minimum required distance from drains is 2 m, irrespective of the number of cylinders.

NOTE 2- Where not more than two cylinders are used, the minimum distance from a boundary is 1 m, unless

the boundary is a firewall, in which case the cylinders may be placed directly against the boundary.

Continue Reading +

NOTE 3- Where more than two cylinders are used, the minimum distance from a boundary is 3 m, unless the

boundary is a firewall, in which case the cylinders may be placed directly against the boundary.

Note 4- Where containers are placed adjacent to a wall on top of which is an electric fence, then a cage is to be installed with the minimum safety distances of A=750mm + B.

Inspection and maintenance (Manifolds and pigtails)

The manifold system should be maintained on a planned inspection basis at intervals not exceeding five years. NOTE, If pigtail/s are exposed to high UV conditions, this period should be reduced.

Continue Reading +

1- A check shall be made to ensure that all safety distances are maintained.

2- Where applicable the enclosure shall be inspected for the condition of any fencing or walling, including the gate. The prescribed signage shall still be in place and legible. ( Commercial or over 100Kg's of gas on a property.

3- The enclosure and immediate surroundings shall be cleared of any uncontrolled weed growth and accumulation of waste products.

4- Repair and maintenance shall only be carried out by a registered installer and the faults in the installation shall be rectified in accordance with the requirements of this part of SANS 10087.

5- Flexible pigtails shall be inspected for signs of rupture, cracking, chafing and perishing and shall be replaced if necessary. If flexible pigtails are over five years old they shall be replaced automatically.

6- The brackets that secure the manifold shall be checked for soundness.

7- The pipework shall be checked for corrosion.

8- All valves shall be checked for free and full range of movement, leakage, positive shut off,

corrosion and mechanical damage.

9- The hydrostatic relief valve on liquid manifolds shall be inspected for corrosion and for any ingress of foreign bodies into the operating mechanism. The relief valve shall be replaced if it is more than five years old.

10- The regulator shall be checked for corrosion and mechanical damage. Where corrosion or

mechanical damage is found the regulator shall be replaced or refurbished.

11- If fitted, gauges shall be checked for correct operation, and gauge faces shall be cleaned.

12- The system shall be leak-tested at all joints using a leak detection solution or system. All

joints where leaks become evident, shall be tightened or remade after the system has been

depressurized.

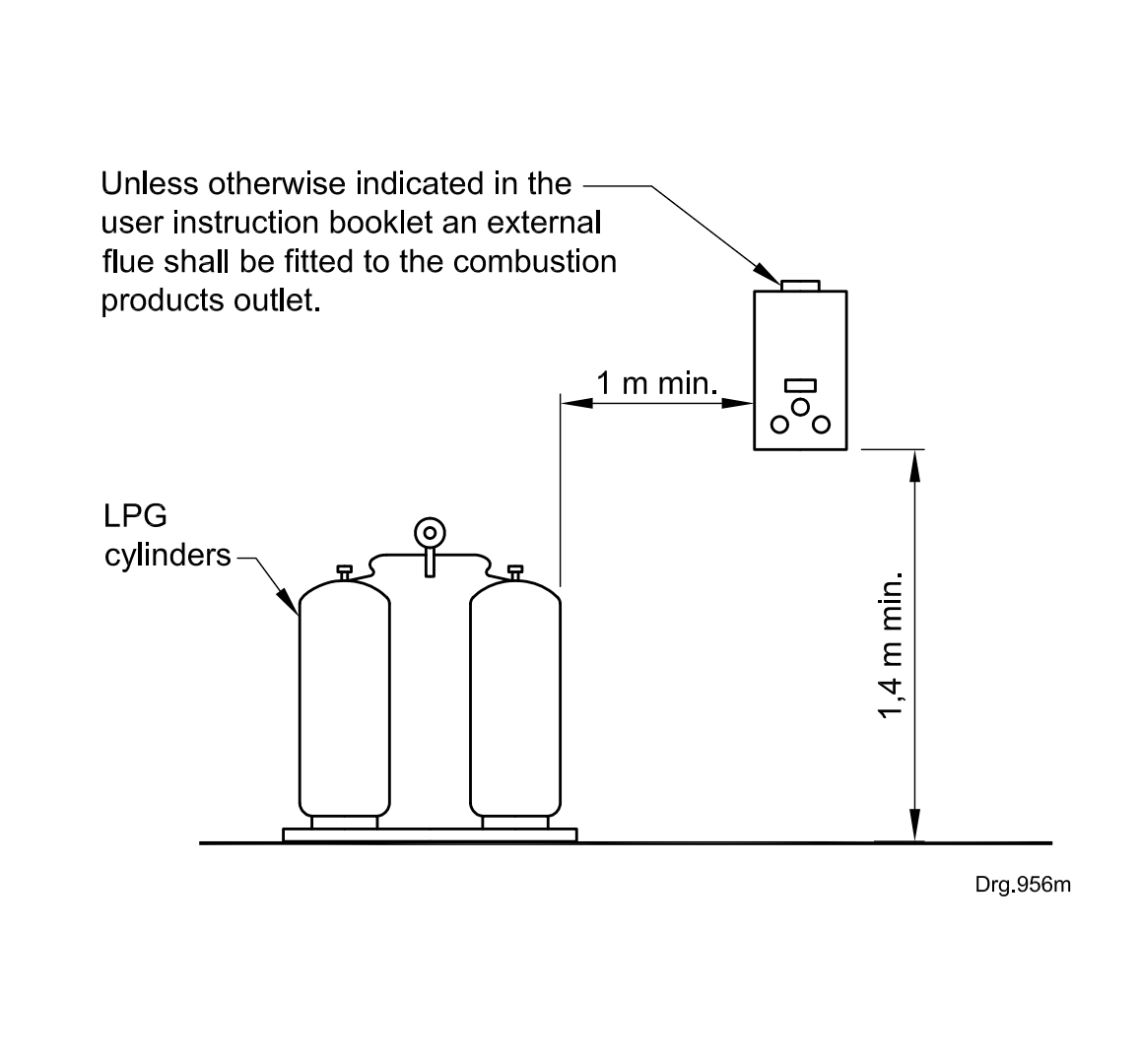

Water Heaters

In any bathroom in which a conventional gas water heater (geyser) is installed, the heater

shall be flued to the outside and provision shall be made to ensure permanent ventilation.

NOTE The manufacturer's operating instructions should be observed

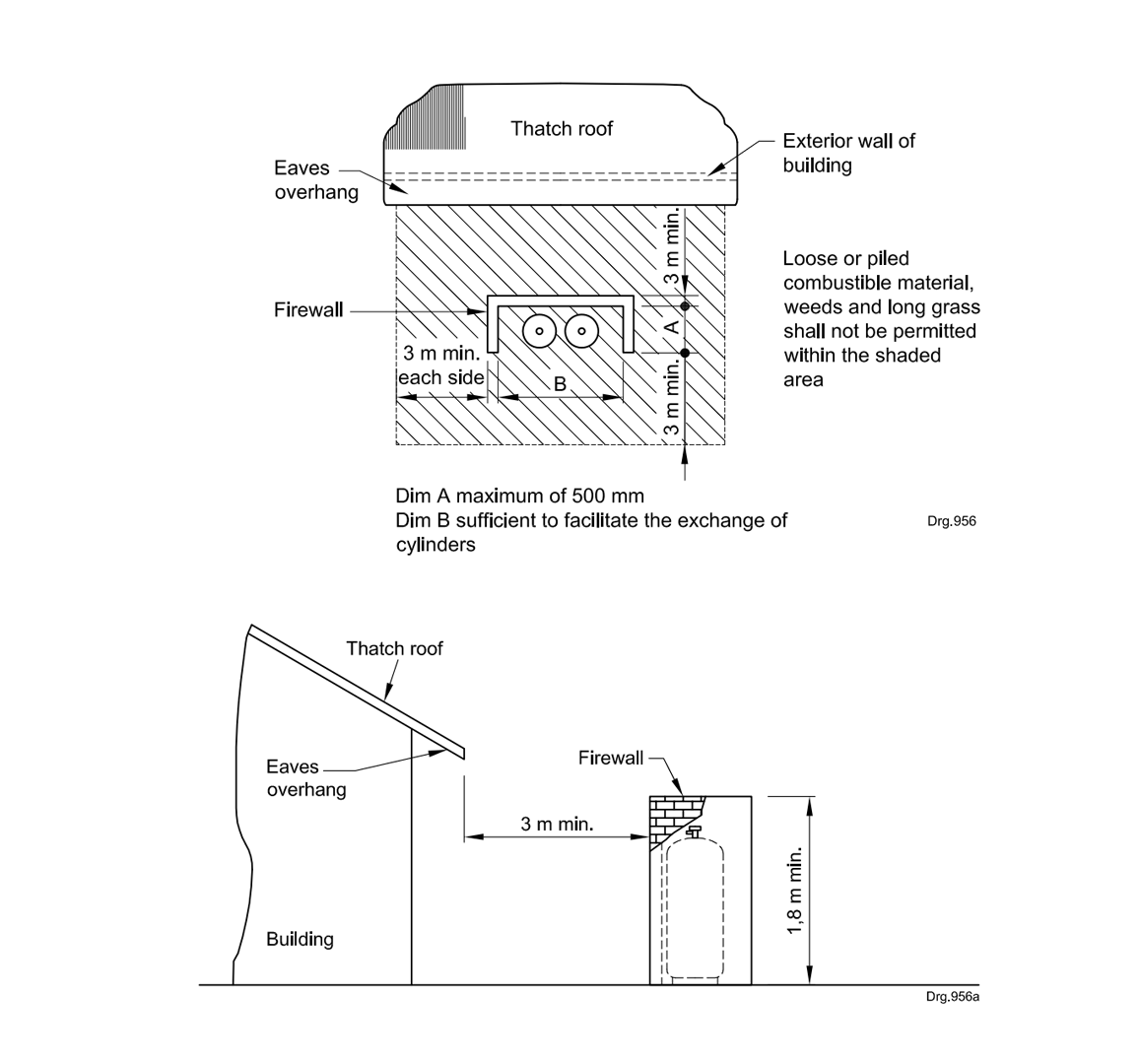

Thatch Roof Distances

Cylinders shall not be installed directly under the eaves of thatched roof. Cylinders shall be not less than 3 m away from eaves of the thatched roof behind a firewall. * We at The LpGas Man don't enforce a firewall if we can achieve a distance of 5m or greater between the cylinders and the thatch roof, Loose or piled combustible material, weeds and long grass shall not be permitted within 3 m of any container

Electric Fence Requirements

Cylinders Placed against a boundary wall with electric fence on the top of the wall shall have a non-combustible roof installed Eg: Gas Cage

Below Window Requirements

Cylinders Placed under a window shall have a non-combustible roof installed Eg: Gas Cage

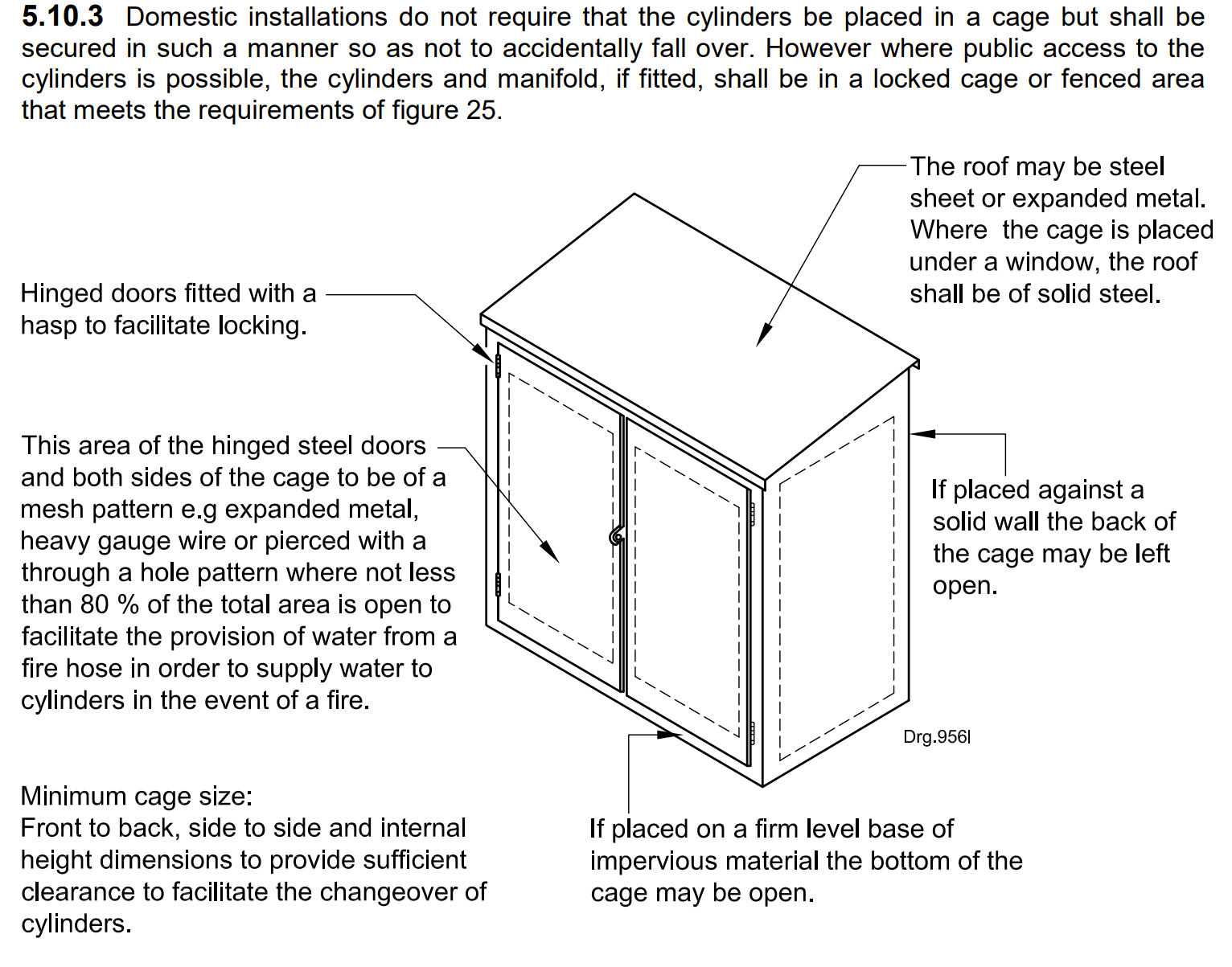

Cage Requirements

Collapsible row

Domestic installations do not require that the cylinders be placed in a cage but shall be secured in such a manner so as not to accidentally fall over Eg: Anchor and chain. However where public access to the cylinders is possible, the cylinders and manifold, if fitted, shall be in a locked cage or fenced area that meets the requirements.

Braai mesh cages is the only cage that provides close to the minimum requirement of 80% ventilation. This requirement is in place to help firefighters cool the cylinders in the event of an emergency. Adequate ventilation can prevent the buildup of potentially dangerous pressure and heat within the gas cages, making it safer for both users and first responders.

Any installation where more than two cylinders are connected shall be fitted with signage

indicating no smoking, no naked flame, no unauthorized entry and no cellular phones allowed, i.e.

the appropriate pictograms

Gas cylinders must not be stored beneath a concrete roof as this poses a significant safety hazard. In the extremely unlikely event of a cylinder explosion, there is a risk of concrete fragments being propelled. Additionally, enclosing gas cylinders with brickwork on three sides is prohibited. It is essential to comply with the 80% ventilation requirement, as this is necessary for the fire department to effectively cool down the cylinder in case of a fire. To meet safety regulations, sides with Braai mesh and a steel roof is pretty much all that is allowed.

Require a Gas Installation? We offer the following services

-

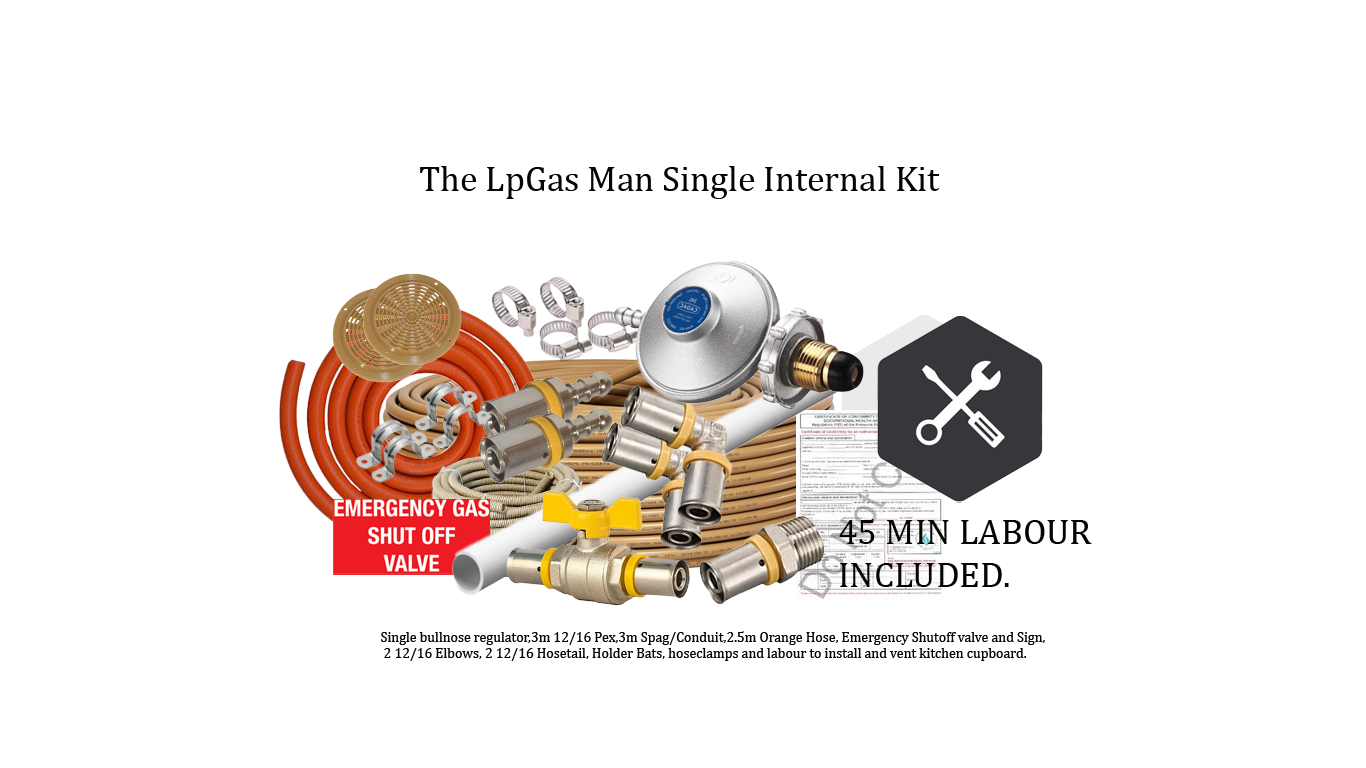

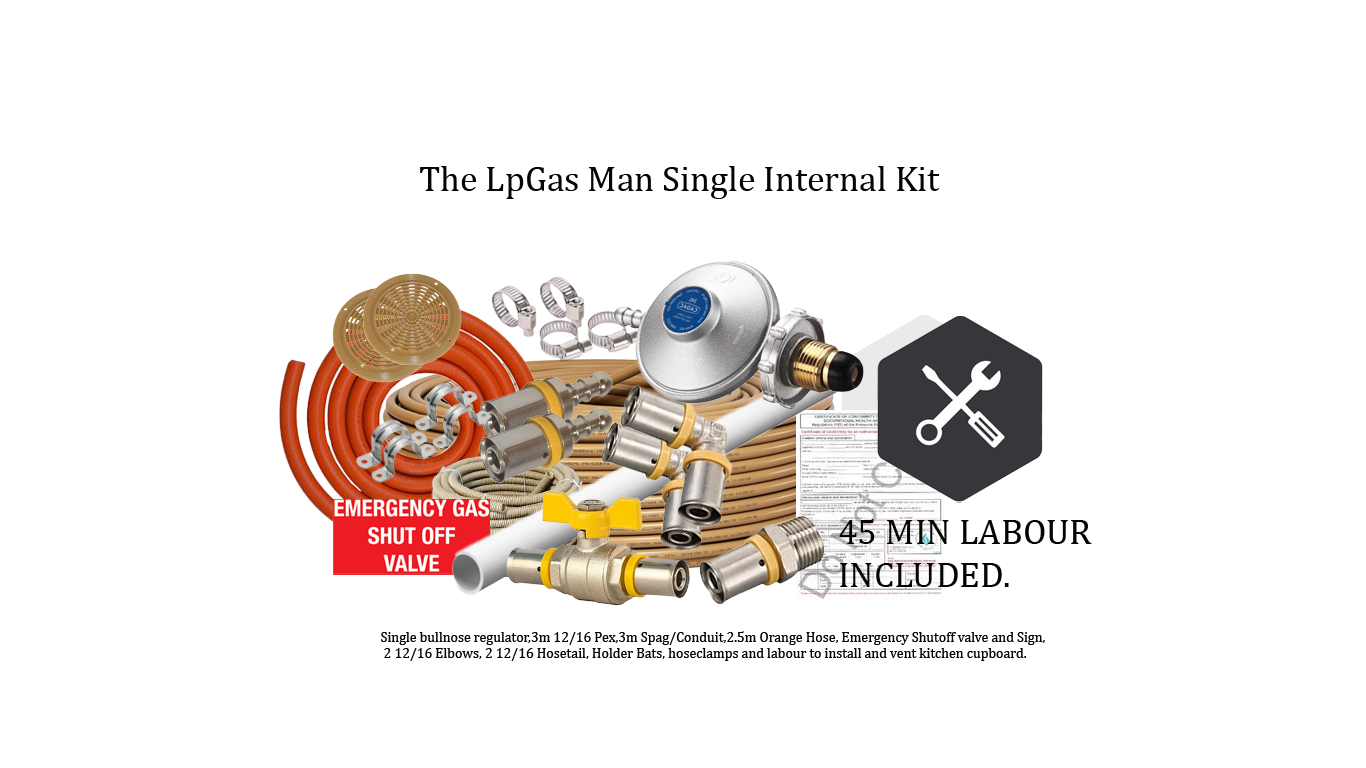

INTERNAL SINGLE - STOVE/HOB INSTALLATION KIT

Internal Installations Here are some instances where an internal installation be the...

-

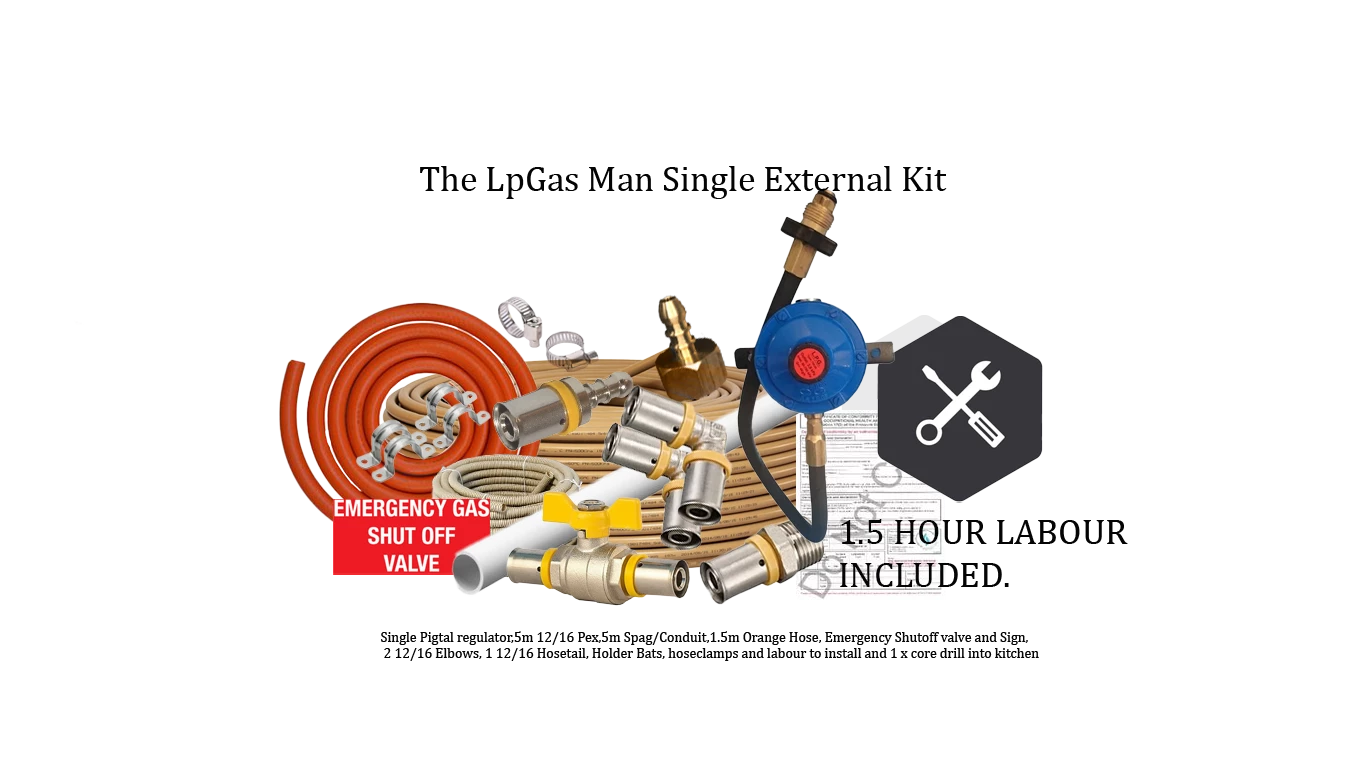

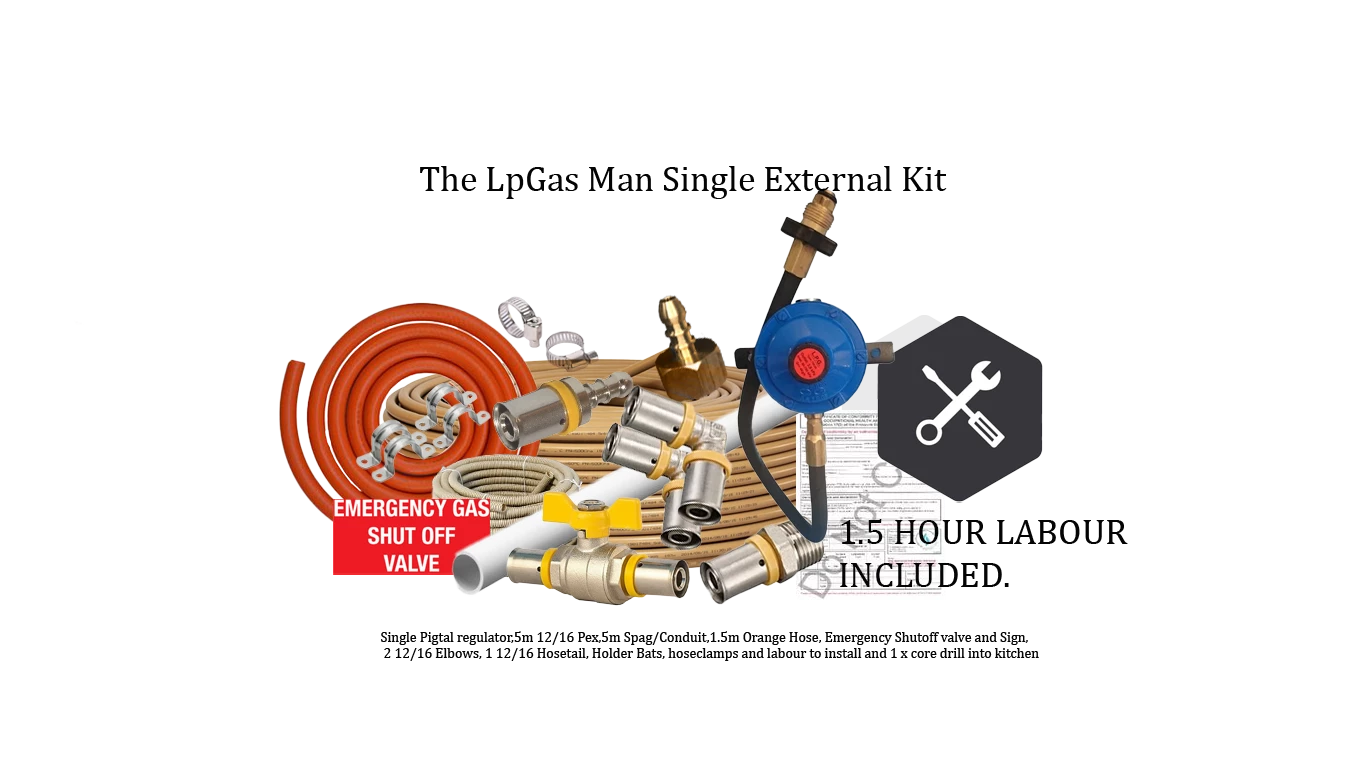

EXTERNAL SINGLE - STOVE/HOB INSTALLATION KIT

Exploring External Installations Consider the advantages of external gas installations, particularly in...

-

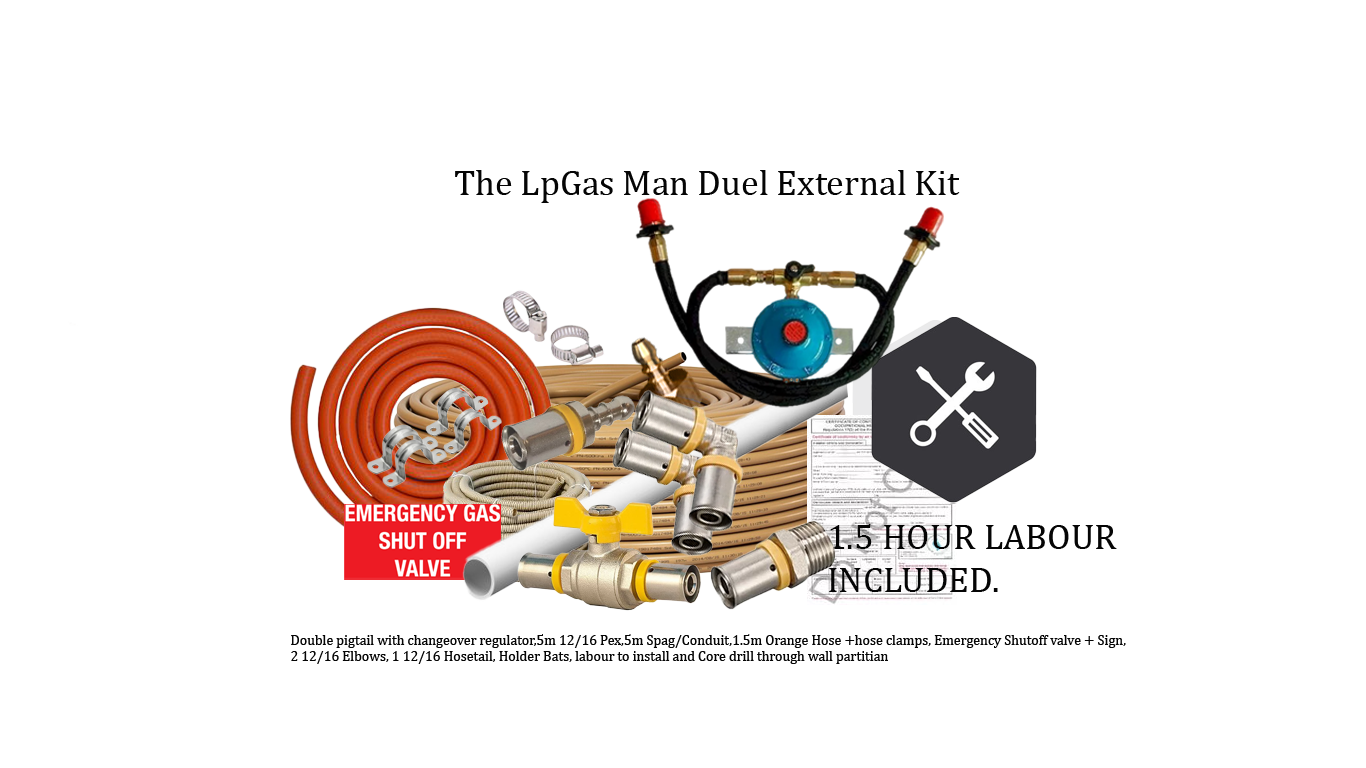

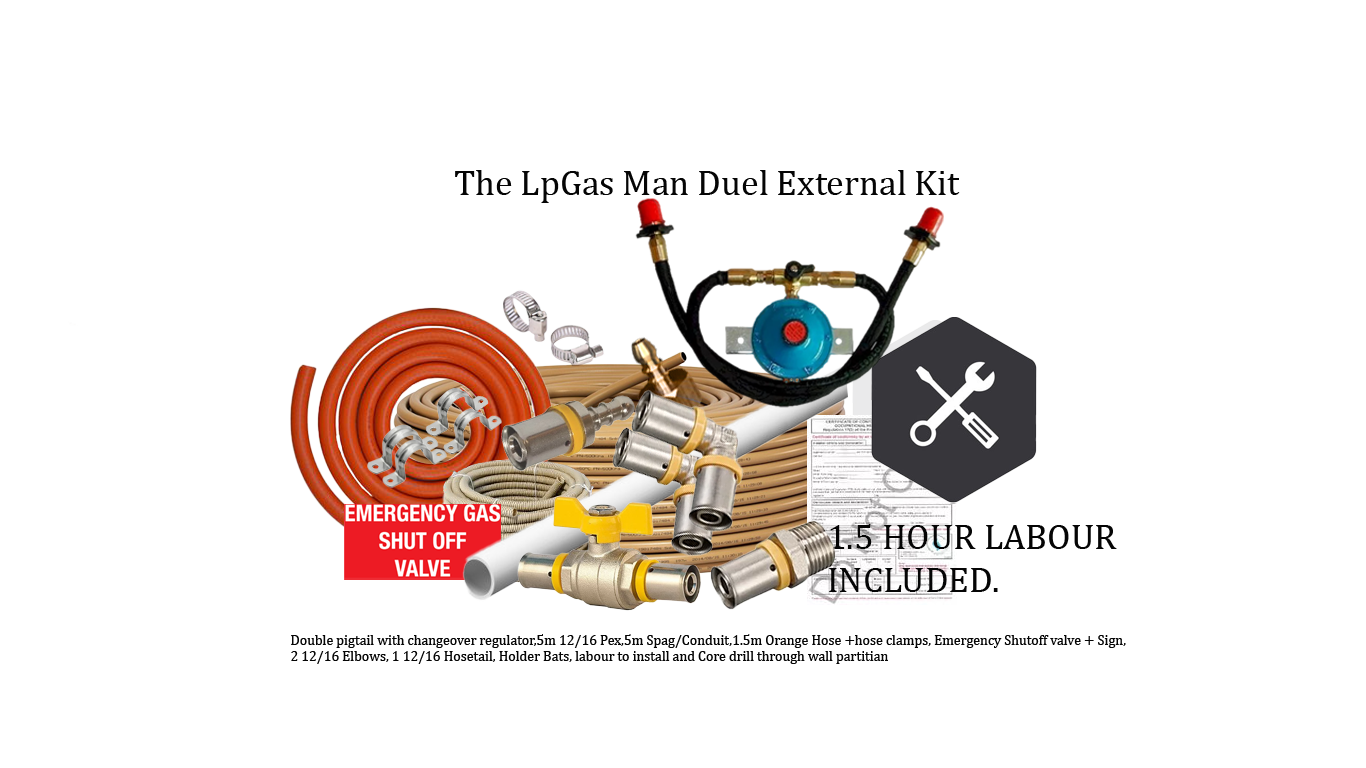

EXTERNAL DUEL - STOVE/HOB INSTALLATION KIT

Exploring External Installations Consider the advantages of external gas installations, particularly in...

Contact us on +27 79-586-9947 or fill in the below and we will get back to you.

Lp Gas Regulations

*Each gas installation/upgrade must be completed in accordance to the regulations of both the South African National Standard (SANS: 10087) and with the Liquefied Petroleum Gas Safety Association of South Africa (LPGSA) and SAQCC Gas.

According to the regulations SANS 10087-1:2013, All gas installations must have a Certificate of Conformity according to the Pressure Equipment Regulations that have been promulgated under the Occupation Health and Safety Act (No 85 of 1993).

While this may sound like a complex, legal document – essentially it is a certificate that states that the installation has been properly inspected and is determined to be safe and leak free. It is critical that this certificate is also issued by an authorized person who is registered with the Liquefied Petroleum Gas Safety Association of Southern Africa (LPGAS) and SAQCC Gas.

So now if your home is damaged or destroyed, as a result of a defective gas appliance and you do not have a valid certificate issued by someone registered with LPGAS – the insurance implications could be significant. An insurance company would be well within their rights to repudiate a claim which could have severe financial repercussions for the home-owner/estate.

Be sure to install with a registered Installer. There are a lot of installers out there that are not registered and this can cause a home owner major problems with insurance company's. Please remember that a plumber is not qualified to install gas unless he can present to you his SAQCC Card.

For all home owners with gas installations already installed on their property or for those planning on doing so in the future, It is vital to ensure compliance with all the above regulations and regulations as stated in the SANS 10087-1:2013 not only to ensure you adhere to stipulations within your home owners insurance policy but to also make sure you and your precious family are safe from any gas related disasters.

Please note that not all the regulations have been placed on this page. This is purely a basic guide from SANS 10087-1:2013.

Why choose us?

As a renowned provider of gas installations, our team with years of experiance are highly skilled and fully registered technicians are dedicated to following all applicable regulations and best practices to guarantee the excellence and safety of our services and our clients. We offer personalized consultations to assist you in determining the most suitable gas line layout and cylinder placement for your specific needs and requirements. With a deep understanding that each customer has distinctive needs, we adopt a customized approach to every project By closely collaborating with you to comprehend your unique requirements. We can deliver tailored solutions that fulfill your needs and surpass your expectations.

External Option 1

Basic Installation kit connecting 1 x 9/19 or 48kg cylinder to a gas appliance consisting of the following:

* 300mm Pigtail

* Astro low pressure wall mounted regulator + Bracket

* Straight Male 12/16 x 3/8

* 5m PEX - AL - PEX PIPE 12/16 Gas line. Additiinal @R75/m

* 2 Pex Elbows 12/16. Additional Elbows @R75/Elbow

* Emergency Shutoff Valve 12/16 Pex

* LPG Gas Emergency Shutoff Valve Plate

* Hosetail 12/16 Pex

* 2m Orange Hose + Clamps

* 1m Chain and anchor

* Conduit Sleeve + Brackets

* Core Drill Through Wall Partition

* Labour

* Issue Lp Gas CoC ( Certificate of Conformity )

- The above breakdown does vary slightly as we use different forms of connections and pipe sizing for different appliances.

- Visit our gas regulations page for ideas on a cyclinder placement.

While the installation of a gas cages is not always required, it may be used in certain circumstances. For example, if a gas cylinder is located under a window, as shown in the image on the left, a gas cage will be used to reduce the horizontal distance between the window and the cylinder from 3 meters down to 600mm. This provides an additional layer of safety. If you dont need a cage but would like a cage installed with a new or existing installation for added protection, We offer a variety of gas cage sizes and styles.

External Option 2

Basic Installation kit connecting 2 x 9/19 or 48kg cylinders to a gas appliance consisting of the following:

* 2 x 300mm Pigtail* Changeover valve

* Astro low pressure wall mounted regulator + Bracket

* Straight Male 12/16 x 3/8

* 5m PEX - AL - PEX PIPE 12/16 Gas line. Additiinal @R75/m

* 2 Pex Elbows 12/16. Additional Elbows @R75/Elbow

* Emergency Shutoff Valve 12/16 Pex

* LPG Gas Emergency Shutoff Valve Plate

* Hosetail 12/16 Pex

* 2m Orange Hose + Clamps

* 1m Chain and anchor

* Conduit Sleeve + Brackets

* Core Drill Through Wall Partition

* Labour

* Issue Lp Gas CoC ( Certificate of Conformity )

The above breakdown does vary slightly as we use different forms of connections and pipe sizing for different appliances.

Call – 079-586-9947

- Gas Installations Fourways

- Gas Installations Broadacres

- Gas Installations Bryanston

- Gas Installations Dainfern

- Gas Installations Dainfern Ridge

- Gas Installations Douglasdale

- Gas Installations Duxberry

- Gas Installations Edenburg

- Gas Installations Jukskei Park

- Gas Installations Kyalami